Lenzkes Clamping Tools

&

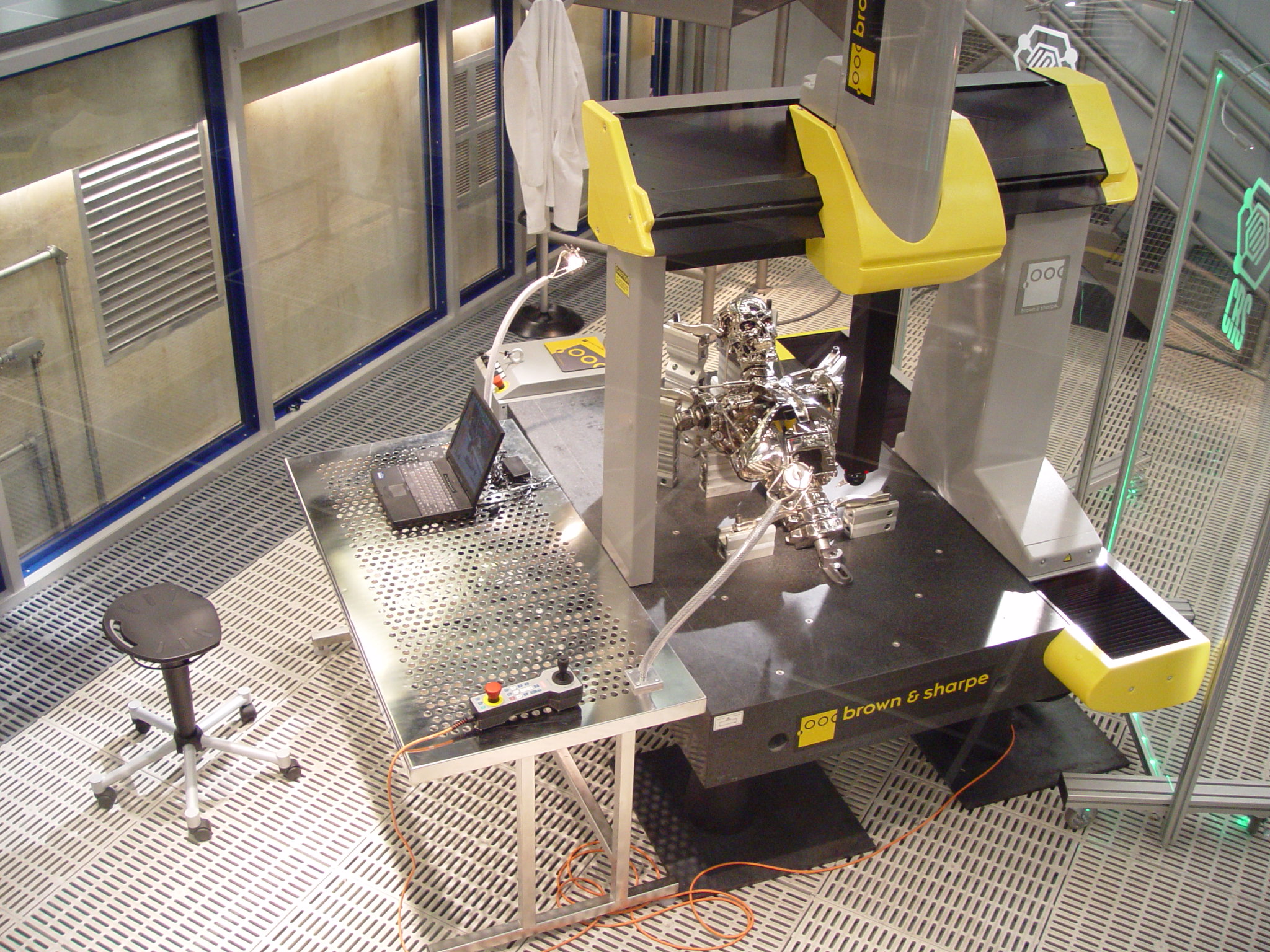

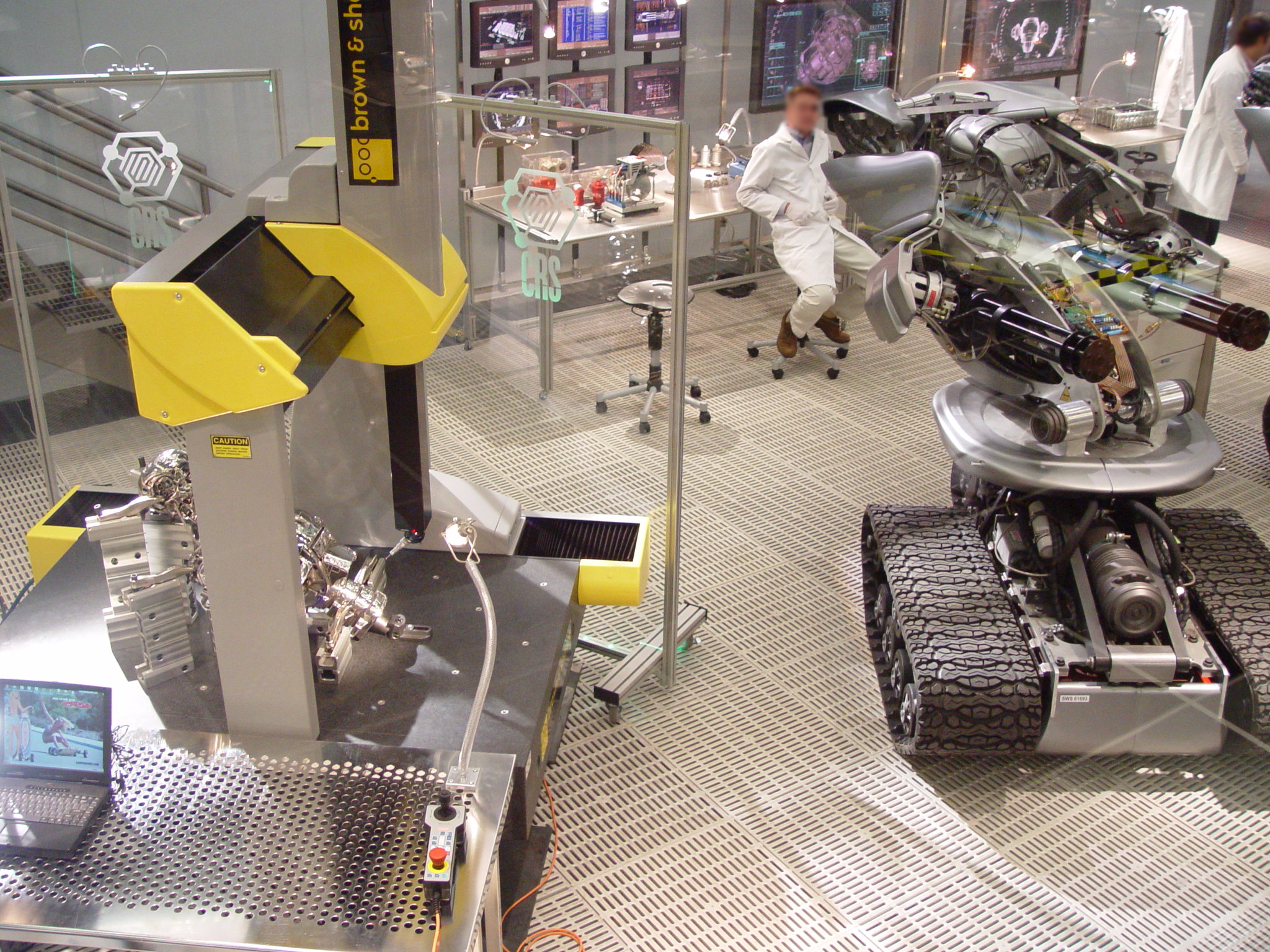

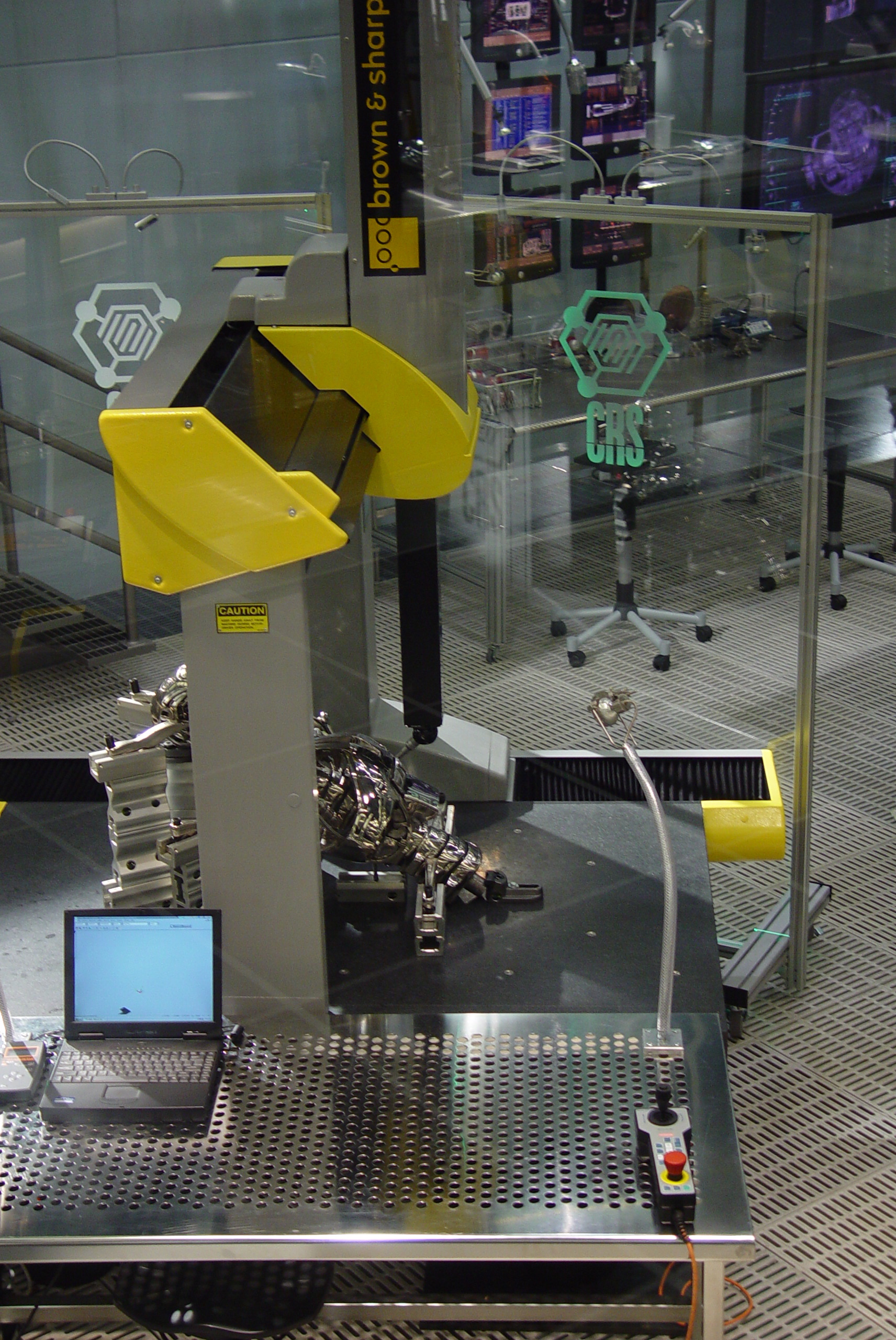

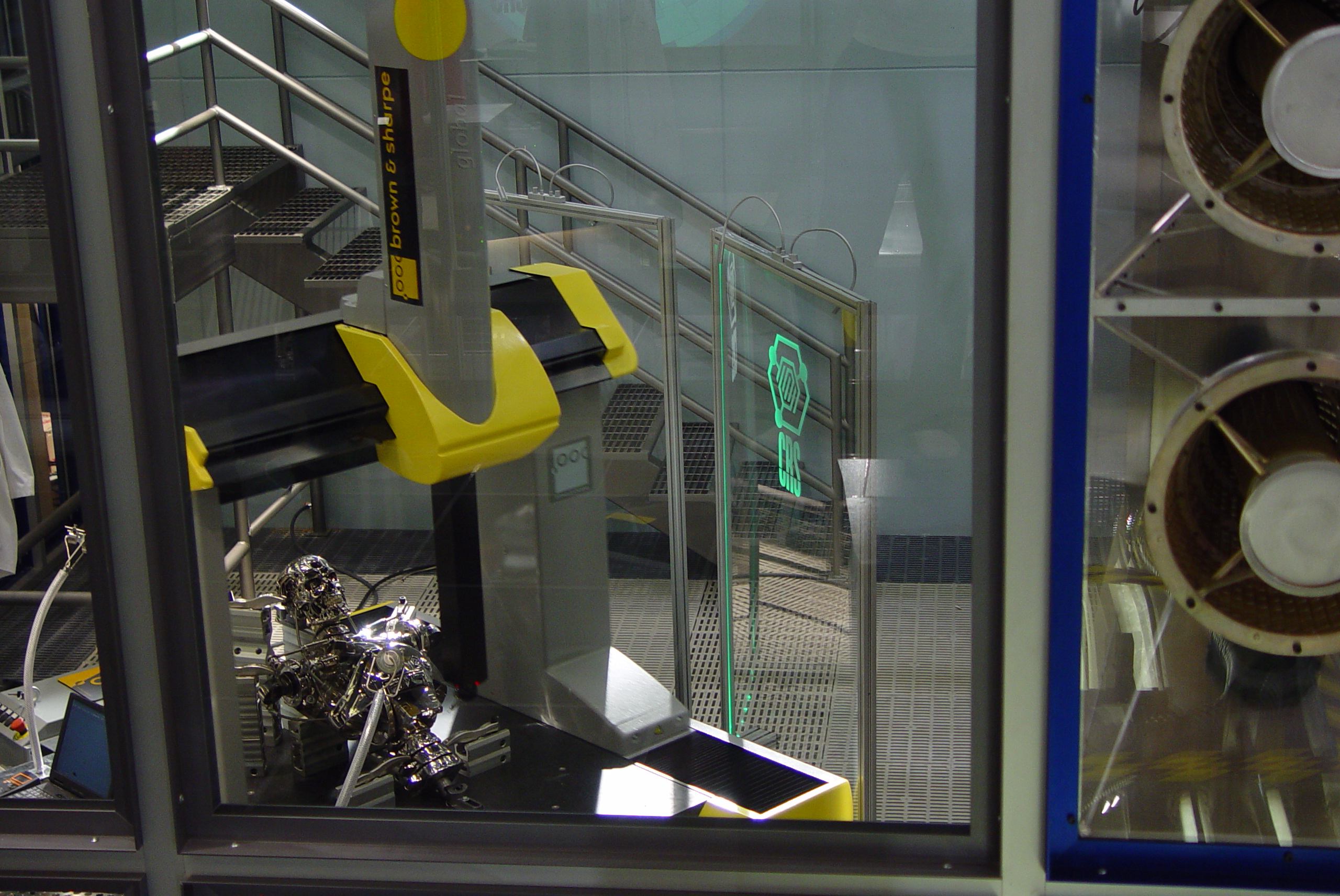

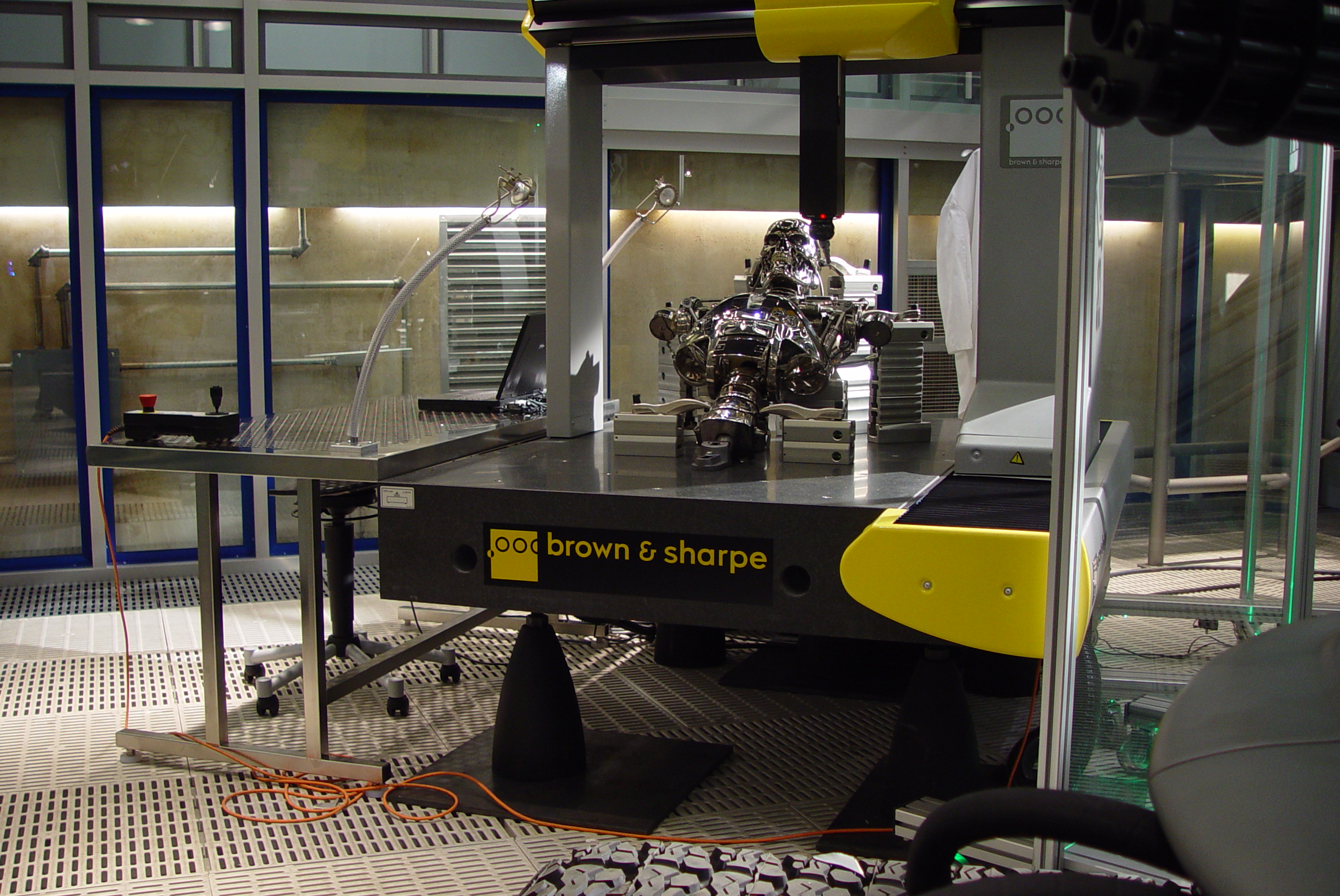

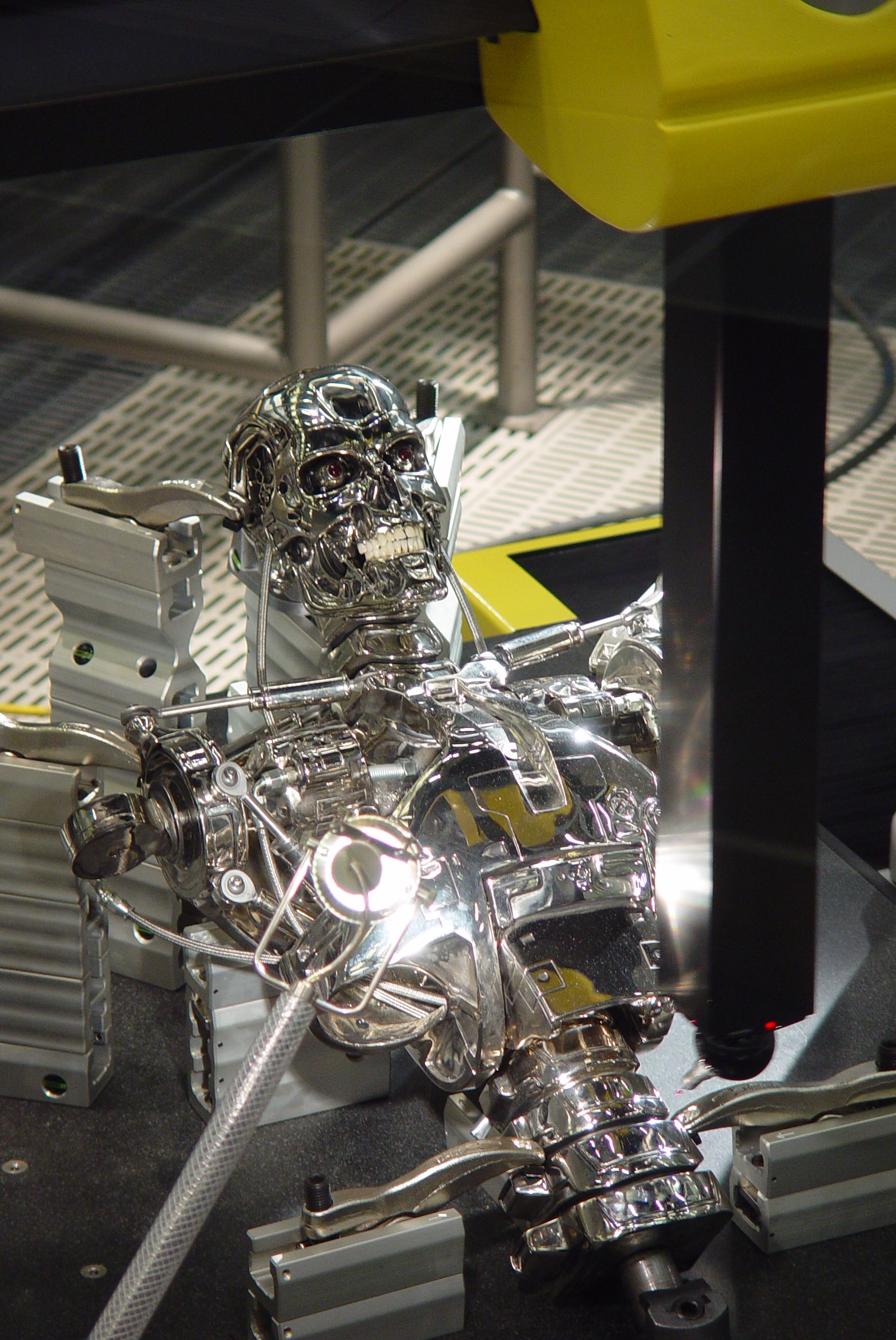

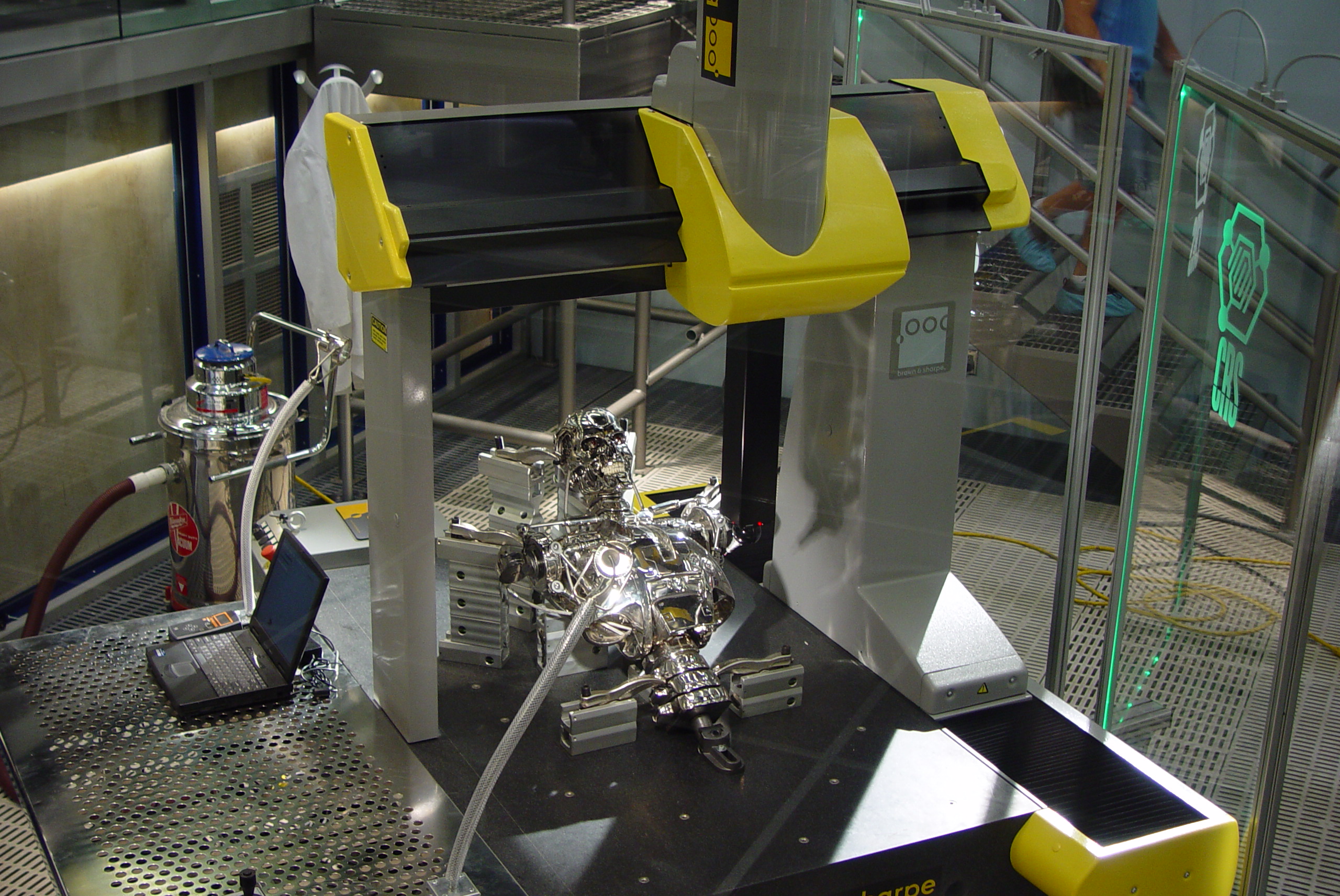

| CHICAGO (June 30, 3 p.m. EDT) - Only the modernistic clamping force of Lenzkes Clamping Tools Inc. can hold down Terminator 3. | ||||||

| That's if you believe posters made from the stills of the new movie Terminator 3: Rise of the Machines, set for a July 2 release. The clamps holding down the Terminator are sold by Christianburg, Va.-based Lenzkes Clamping Tools, and made in Ludenscheid, Germany, by its parent Lenzkes Spanntechnik GmbH. | ||||||

| "They're holding a torso, one robotic head, an arm, a leg - I felt as if we are working for a medical company," quipped Michael Brocher, Vice President of Lenzkes Clamping Tools, in an interview at NPE. | ||||||

| The clamping system with the sleek look can be made in sizes up to a clamping force of 18,000 foot pounds and feature an easy release system using a torque wrench. The parts are aluminum or stainless steel and " are not cast, but forged," he noted. | ||||||

| Brocher said that they are eagerly awaiting the release of the film. But the placement was not part of the company's marketing plan, but rather an opportunity that arose from a chance meeting at a trade show in Anaheim, Calif., back in February 2002. | ||||||

| He said two men walked in, looked over the product, and said they were interested in using the clamps on the Terminator set. Brocher told them it was company policy to allow customers a free trial, anticipating that the product could sell itself. | ||||||

| "Both were engineers in the decorating sets and said we never saw anything like this it is really modern and the modernistic tool of the future," Brocher said. | ||||||

| Within a week he had a request for trial parts. Eventually he shipped a pallet of the clamps to Hollywood. | ||||||

| The movie has not had an effect yet on business, but trade shows have. Brocher said the company has purchased eight acres of land in Montgomery County, Va., and plans to start building a 30,000-square-foot facility in September. | ||||||

| Right now, Lenzkes has a 10,000-square-foot building in Christiansburg for assembly and sales work. | ||||||

| Lenzkes has side and top clamping systems and is picking up more work in Canada and Mexico. | ||||||

| "With lean manufacturing, quick release systems are changing companies. Anything that makes machines faster or the production of a person higher are sought after," said Brocher. He said ease of use can cut the time of a mold change by up to forty minutes, but the average savings is 20-30 minutes. | ||||||

| Oh, and about that movie: The film crew has returned most of the clamps, but kept a few in case Arnold Schwarzenegger decides to do Terminator 4. | ||||||

| * Article courtesy of Plastics News. | ||||||

|

|

|

|

|||

|

|

|

|

|||